双数控全自动切捆条机

KL-286SK 双数控全自动切捆条机

KL-286SK automatic edge vertical

diagonal cloth rolling machine

适用范围:

平推式全自动切条机及直纹,45度斜纹卷布机适用于布料、无纺布、帐篷、雨伞、泡棉、皮革、反光材料、塑胶、纸张、双面胶、醋酸布、补强带、导电布、铜箔等材料各种宽度直条,横条及45度直斜条的卷布及裁切是服装、箱包、鞋帽、服装辅料、反光材料厂、帐篷厂、雨伞厂、电子厂等行业的理想选择。

技术参数:

布料幅宽:1.7米(另有2.05米、2.4米可选)

布料转速:0-1200 (转/分钟)

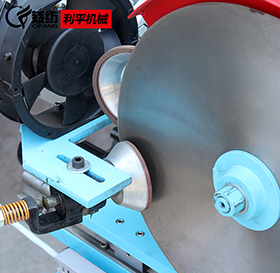

切布直径:300毫米,也可定制400毫米

布轴直径:38毫米布料

电机功率:0.75千瓦

刀片电机功率:1.5千瓦

最小切条宽度:2毫米

电压:380V/220V可选

外形尺寸:2.8米x0.85米x1.5米

配备特点:

(1)主轴以及圆刀使用无级变速系统,可做高低无级调速及正反转切换控制。

(2)台板左右移位和进退刀均采用进口高精密步进系统及进口PLC控制切割宽度及进退刀切割和磨刀系统,配合进口精密滚珠丝杆及滑轨移位,高寿命,不易磨损,使切割宽度的精度达到0.1mm,最窄切割宽度为2mm,进刀切割时平行快速推进,速度采用无极调速,可分段控制,纸管容易切断,达到高精度快速切出高品质的产品。

(3)操作界面采用电脑触摸屏,所有操作,只需要一个画面,可同时设定六种分切宽度和次数,并显示实际切割次数,并设有手动/自动转换及磨刀手动/自动转换功能。

(4)在手动功能下,设有十字摇杆手柄,操作更加人性化!更加便捷,移动速度更快,移动的同时,可以在触摸屏上显示移动的宽度,达到更加精准。

(5)配备数控自动双面磨刀系统,电脑控制砂轮,自动进退,并根据刀片大小自动定位,可设定磨刀次数及时间,自动启动旋转,自动停止,采用金刚石砂轮磨削,经久耐用,不易发热,刀片磨后光洁度高,使用寿命是普通白玉刚砂轮的几倍,刀片不用拆卸,即可磨刀。刀片长期保持锋利,保证裁切质量,并附有自动吸尘装置,保持布料及轨道清洁。

(6)采用快速放料设计,一步到位。上料下料只须一个动作即可完成。

(7)电路采用各个独立控制系统,每条线都做有标号,诊断维修简单快捷,不易出故障。

(8)夹布卡盘配有安全防护罩,不伤人。电线配有工程塑料链条保护,电线不容易折断,不容易老化。

Scope:

Flat push automatic cutting machine and the ruled, 45-degree diagonal rolling machine for fabrics, woven fabrics, tents, umbrellas, foam, leather, reflective material, plastic, paper, double sided tape, acetate cloth, reinforced belt, conductive cloth, copper and other materials of various width straight, straight bar and 45 ° oblique cut of the cloth and roll apparel, bags, shoes, clothing accessories, reflective material factory, tent factory, umbrella factory, electronics factory and other industries the ideal choice.

Technical parameters:

Fabric width: 1.7 m (another 2.05 meters, 2.4 meters optional)

fabric speed :0-1200 (rev / min)

Cloth Diameter: 300 mm, 400 mm can also be customized

fabric shaft diameter: 37 mm

Fabric Motor power: 0.75

kilowatts Blade motor power: 1.5 kilowatts minimum

cutting width: 2 mm

Voltage: 380V/220V

optional Dimensions: 2.8 m x1.5 m x0.85 m

Equipped with features:

1, circular knife spindle, and use the CVT system, do the level of variable speed and reversing switch.

2, platen displacement and retreat around the knife are made of imported high-precision stepper PLC control system and imported cutting width and cutting and knife sharpening system, advance and retreat, with the import of precision ball screw and slide the shift, the high life, easy to wear , so that the width of the cutting accuracy of 0.1mm, the narrowest cutting width of 2mm, cutting parallel to the fast feed advance speed with stepless speed, can be sub-control paper tube is easy to cut, to cut out high-precision high-quality fast products.

3, the use of computer touch-screen interface, all operations, only one screen, you can also set the width and cut the number of six kinds, and show the actual cutting times, and with manual / automatic conversion and sharpening manual / automatic conversion.

4, the manual functions, the rocker has a cross handle, operate more humane! More convenient, moving faster, moving at the same time, you can move on the touch screen display width, to be more precise.

5, automatic two-sided sharpening system with numerical control, computer control wheel, automatic advance and retreat, and automatic positioning according to blade size, frequency and timing of sharpening can be set to automatically start the rotation, auto-stop, using the diamond grinding wheel, durable, easy to heat, high finish after grinding blades, grinding wheels of life ten times the ordinary Baiyu Gang, without disassembling the blades, you can knife. Long-term sharp blade, to achieve the best cutting quality, along with automatic cleaning devices to keep track of cloth and clean.

6, using fast discharge design, in one step. Cutting only on the material to complete an action.

7, each individual circuit control system, each line has done a label, diagnostic maintenance quick and easy, not easy to fail.

8, Buka folder with security cover plate, not hurt. Chain with a plastic wire protection, cable is not easily broken, is

not easily broken,is not easy to aging.